Lube Oil Purification Temperature . The first stage in the lube oil purification process involves the particle filtration system. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. What does a lube oil cleaning circuit look like today? continuous lubricating oil cleaning during engine operation is mandatory. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. particle filtration system: When cleaning engine lube oil, the oil. These oils can be purified and reused. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. An optimal lubricating oil treatment is fundamental. 10 questions and answers. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”.

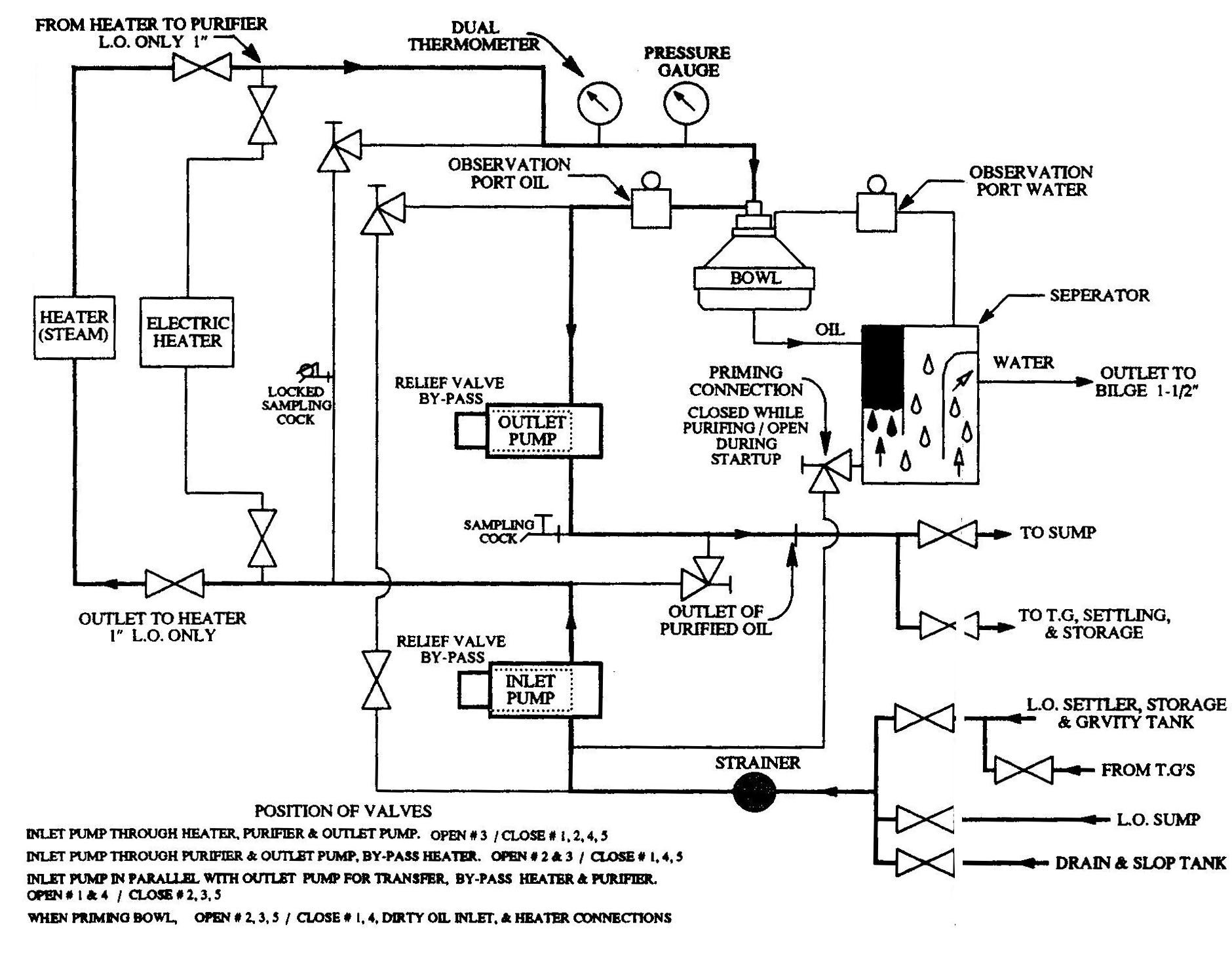

from weh.maritime.edu

These oils can be purified and reused. The first stage in the lube oil purification process involves the particle filtration system. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. 10 questions and answers. two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. continuous lubricating oil cleaning during engine operation is mandatory. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. An optimal lubricating oil treatment is fundamental. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove.

TSPS Engineering Manual

Lube Oil Purification Temperature These oils can be purified and reused. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. An optimal lubricating oil treatment is fundamental. particle filtration system: What does a lube oil cleaning circuit look like today? continuous lubricating oil cleaning during engine operation is mandatory. The first stage in the lube oil purification process involves the particle filtration system. two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. These oils can be purified and reused. When cleaning engine lube oil, the oil. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. 10 questions and answers.

From purifiedlubricants.com

Oil Purifications Systems for Sale Purified Lubricants Lube Oil Purification Temperature The first stage in the lube oil purification process involves the particle filtration system. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. continuous lubricating oil cleaning during engine operation is mandatory. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. These oils can be purified and reused. Web. Lube Oil Purification Temperature.

From www.chinaoilpurifier.com

How Temperature Affects Lubricants? Chinaoilpurifier Lube Oil Purification Temperature two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. These oils can be purified and reused. When cleaning engine lube oil, the oil. continuous lubricating oil cleaning during engine operation is mandatory. 10 questions and answers. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. What. Lube Oil Purification Temperature.

From www.yunengoilpurifier.com

Lube Oil Purifier YUNENG Lube Oil Purification Temperature An optimal lubricating oil treatment is fundamental. two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. When cleaning engine lube oil, the oil. 10 questions and answers. alfa laval centrifugal oil separators provides you with an effective. Lube Oil Purification Temperature.

From purifiedlubricants.com

Oil Purifications Systems for Sale Lubricating Oil Purified Lubricants Lube Oil Purification Temperature two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. An optimal lubricating oil treatment is fundamental. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. What does a. Lube Oil Purification Temperature.

From www.hention.com

VLP Lubricating Oil Purification System HENTION HENTION Lube Oil Purification Temperature Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. particle filtration system: 10 questions and answers. continuous lubricating oil cleaning during engine operation is mandatory. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. The first stage in the lube oil purification process. Lube Oil Purification Temperature.

From www.youtube.com

Rundown Tank Lube Oil System ProcessAnimation 2022 YouTube Lube Oil Purification Temperature alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. continuous lubricating oil cleaning during engine operation is mandatory. 10 questions and answers. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120. Lube Oil Purification Temperature.

From www.cnoilpurification.com

Lubricating Oil Purifier归档 CHONGQING CUMWAN OIL PURIFIER CO.,LTD Lube Oil Purification Temperature particle filtration system: An optimal lubricating oil treatment is fundamental. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. F) in a process that accelerates moisture evaporation with minimal risks of oil. Lube Oil Purification Temperature.

From www.cqpuretech.com

Turbine Lube Oil Purification System Lube Oil Purification Temperature An optimal lubricating oil treatment is fundamental. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. What does a lube oil cleaning circuit look like today? Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and. Lube Oil Purification Temperature.

From atpspl.com

Lube Oil Filtration Associated Thermal Power Systems Pvt. Ltd Lube Oil Purification Temperature particle filtration system: two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. When cleaning engine lube oil, the oil. These oils can be purified and reused. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove.. Lube Oil Purification Temperature.

From www.rexonop.com

Multi Functional Lubricating Oil Purifier Lube Oil Dehydrator Lube Oil Purification Temperature particle filtration system: alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. The first stage in the lube oil purification process involves the particle filtration system. When cleaning engine lube oil, the oil. two commonly used vacuum dehydration processes are “vacuum mass transfer” and “flash distillation.”. Web. Lube Oil Purification Temperature.

From flocomponents.com

SKF CircOil Lube System FLO Components, Value Added Partner and Lube Oil Purification Temperature An optimal lubricating oil treatment is fundamental. continuous lubricating oil cleaning during engine operation is mandatory. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. The first stage in the lube oil purification process involves the particle filtration system. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and. Lube Oil Purification Temperature.

From www.marineinsight.com

Ship's Main Engine Lubrication System Explained Lube Oil Purification Temperature lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. When cleaning engine lube oil, the oil. alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. These oils can be purified and reused. 10 questions and answers. F) in a process that. Lube Oil Purification Temperature.

From www.coalhandlingplants.com

Steam Turbine Lube Oil System in Thermal Power Plant Lube Oil Purification Temperature These oils can be purified and reused. An optimal lubricating oil treatment is fundamental. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. The first stage in the lube oil purification process involves the particle filtration system. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. 10 questions and answers. Web. Lube Oil Purification Temperature.

From www.chinaoilpurifier.com

Lube Oil Purifier Strong Purification Ability Chinaoilpurifier Lube Oil Purification Temperature Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. An optimal lubricating oil treatment is fundamental. What does a lube oil cleaning circuit look like today? continuous lubricating oil cleaning during engine operation is mandatory. F) in a process that. Lube Oil Purification Temperature.

From www.zyoilpurifier.com

Addordable Lube/Hydraulic Oil Purification System Manufacturer ZANYO Lube Oil Purification Temperature alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. These oils can be purified and reused. The first stage in the lube oil purification process involves the particle filtration system. particle filtration system: Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. lubrication oil. Lube Oil Purification Temperature.

From www.oilpurifiermachine.com

Selected Materials Portable Lube Oil Purifier / Bearing Oil Lube Oil Purification Temperature alfa laval centrifugal oil separators provides you with an effective solution to clean your industrial lubrication oils and extent. continuous lubricating oil cleaning during engine operation is mandatory. Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. The first stage in. Lube Oil Purification Temperature.

From weh.maritime.edu

TSPS Engineering Manual Lube Oil Purification Temperature F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. continuous lubricating oil cleaning during engine operation is mandatory. particle filtration system: Vacuum mass transfer uses moderate vacuum levels (ࣘ≤22inhg) and heat (≤120 deg. The first stage in the lube oil purification process involves the particle filtration system. alfa laval centrifugal oil separators. Lube Oil Purification Temperature.

From www.oilrecondition.com

Lubricating Oil Vacuum Purifier,Top Efficiency Tools Lube Oil Purification Temperature continuous lubricating oil cleaning during engine operation is mandatory. F) in a process that accelerates moisture evaporation with minimal risks of oil degradation. 10 questions and answers. lubrication oil purifiers, also known as oil cleaning systems, are specialized machines designed to remove. alfa laval centrifugal oil separators provides you with an effective solution to clean your. Lube Oil Purification Temperature.